Capabilities

Through precision manufacturing, the use of advanced technology, and expert craftsmanship, our deep draw metal stamping company in West Michigan has grown into a worldwide industry leader trusted by many. At Trans-Matic, we take pride in bringing custom solutions to life with industries who, like us, demand the highest standards and prioritize not just quality and efficiency, but innovation as well.

Familiarize yourself with all that we do down below. If you’re looking to get started on a new deep draw stamping project, fill out our online contact form today and someone from our team will reach out to you.

Deep draw stamping is a specialized metal forming process that transforms flat sheet metal into three-dimensional shapes with significant depth. It involves drawing the metal sheet into a die cavity using a punch. The process is characterized by stretching and compressing the metal to achieve the desired shape, often requiring multiple drawing operations to form the final component.

Transfer press stamping has evolved to meet the growing demand for high-volume, intricate metal components. With single-stroke stamping, complex components can be expensive and labor-intensive, requiring technicians to manually reposition parts at multiple presses. Instead, transfer press stamping automates multiple operations, making it easier to create detailed metal components such as those for cars, light fixtures, HVAC systems, aerospace products, and more.

In progressive die stamping, the press uses an automatic feeding system to push a strip of metal through each stamping station. Each station performs one or more operations throughout the part-production process. The final station serves as a cutoff operation, which separates the finished part from the carrying web which, along with metal punched away in previous operations, becomes scrap. With each stroke/cycle of the press, one or more completed parts get cut off and removed from the die.

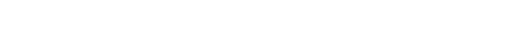

Trans-Matic has a dedicated advanced product development team that will work with you on your custom design. Our engineers will gain familiarity with the specific needs and dynamics of your product while it is still in the conceptual stages to create prototypes. Whether you only have an idea sketched on a napkin or complete CAD files for your product, we have the design, engineering, and manufacturing capabilities to deliver the high precision, high quality stamped parts you need.

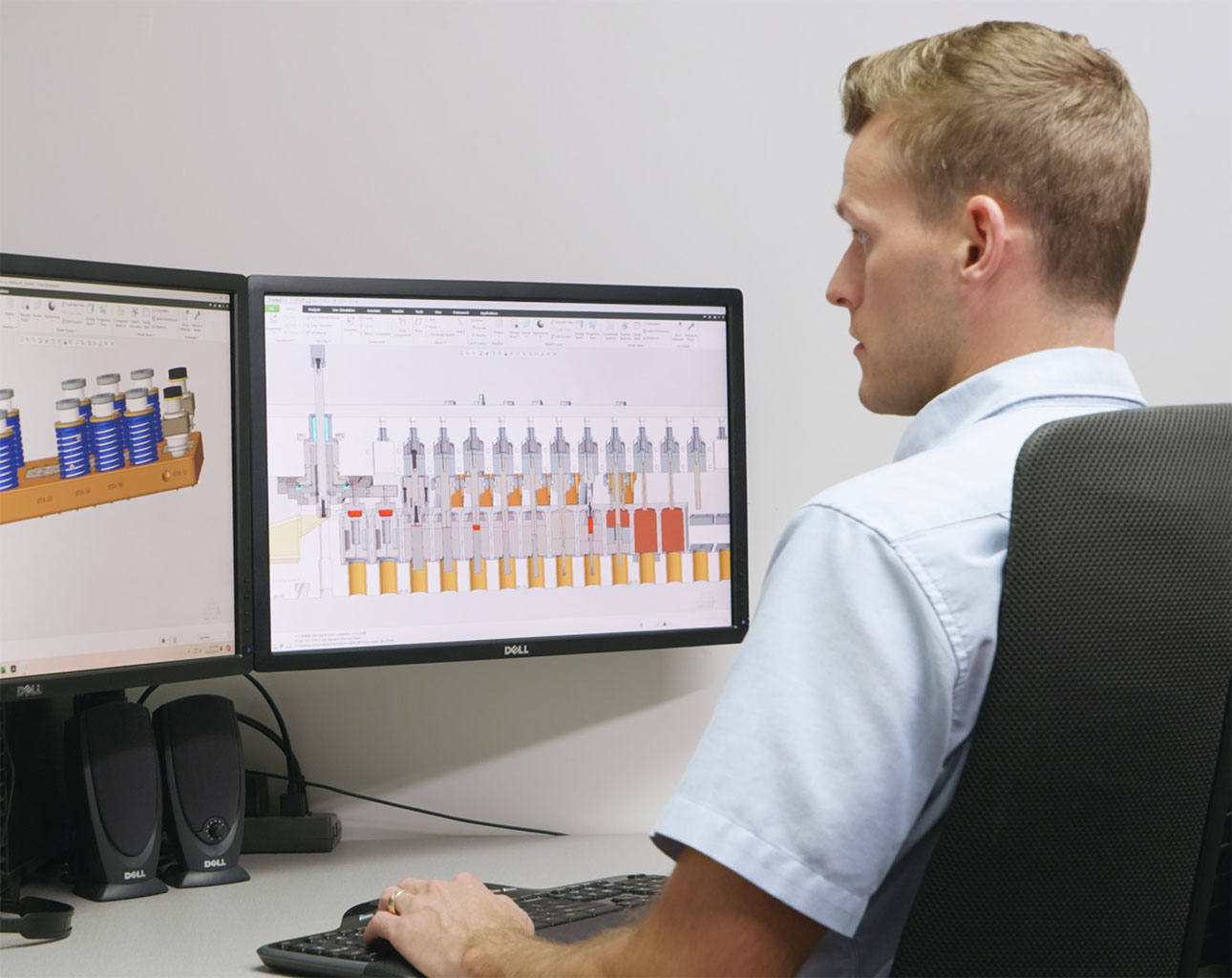

To add further value to our deep drawn metal stampings, we provide several optional secondary services. These processes, including fully automated assembly, non-destructive testing, crimping, boring, and more are performed in-house to ensure that finished parts meet or exceed customer expectations and Trans-Matic’s high quality standards.

Trans-Matic produces precise, high quality deep drawn parts using a wide range of deep draw stamping materials like low carbon steel, stainless steel, aluminum, and more. We work with raw materials up to 0.180” (4.5mm) thick, and can create parts up to 9.5” (240mm) long. We will work with you, as needed, to determine the best material for your parts based on application, performance and manufacturing requirements.