Our Story

West Michigan's First Deep draw Company

Founded on Family, Stamped With Trust

Founded in 1968, Trans-Matic was the first deep draw metal stamping company in West Michigan. Starting out with only two presses, Pat Thompson built the company on a simple premise: to provide high-quality, dependable metal stampings of the highest caliber across a diversified market. That’s where our story begins.

Since then, we’ve developed a seasoned, global team of toolmakers, engineers, die designers and support personnel. Together, our team has earned an international reputation for customer loyalty. Customers know when they choose Trans-Matic, they get technically sophisticated solutions, on-time deliveries and high-performing precision components. Ask around and you’ll find that our customer feedback is consistent: “the most reliable and capable metal stamping firm in the industry.”

Founded by Pat Thompson

The Thompson family sells their house in Chicago to start a deep draw metal company in Holland, MI. The company is new and undercapitalized, but its people are filled with hope and determination. At the end of the year, founder Pat Thompson sits down with the company accountant and discovers Trans-Matic had turned a small first-year profit: $699.

Company Project for a Few Good Men

The United States Department of Defense (DOD) waits by the front door as Pat Thompson arrives to work one morning, sending Trans-Matic on one of the most unexpected and significant projects of the last 50 years. Through the Honeywell project, the team at Trans-Matic has the chance to support the boys over in Vietnam: an opportunity they will never forget.

Groundbreaking of New Holland, MI Plant

As the first company in the area and the metalforming industry with a profit-sharing program, Trans-Matic communicates a new kind of care and support for company employees and moves their headquarters to the current 48th Street location in Holland, MI.

Pat Thompson Appointed PMA Chair

The Precision Metalforming Association (PMA) is the full-service trade association representing the multibillion dollar metalforming industry of North America. Pat Thompson steps up as PMA Chair to help lead the association at an exciting time–just a couple of years prior to the association’s first Automotive Parts Suppliers Conference in Detroit, MI.

Expansion of Holland Facility

The Holland, MI facility nearly doubles to 238,000 square feet with fresh capacity for transfer and progressive presses as well as value add and value engineering solutions. This growth was spurred by the global manufacturing trend of outsourcing production to suppliers for highly skilled, capital-intensive work.

PJ Thompson Appointed Company President

PJ Thompson continues the company legacy by bringing the same fiscal responsibility and mission for growth as his father, but with a vision for Trans-Matic’s future that is distinctly his own.

Opening of Suzhou, China Facility

For the first time, Trans-Matic expands to a new continent in order to better supply Asian clients with locally sourced parts at a location closer to home. Trans-Matic’s strategy is to supply deep-draw component parts to the local market.

PJ Thompson Appointed PMA Chair

PJ aids the PMA in continuing to realize its mission to shape the environment of the metalforming industry, leading innovative member companies toward superior competitiveness and profitability.

Opening of Monterrey, Mexico Facility

Continuing its commitment to global growth, Trans-Matic opens a new manufacturing facility in Monterrey, Mexico. This expansion extends our reach across the Americas, ensuring customers benefit from localized production and seamless service worldwide.

Relocation of Suzhou, China Facility

Trans-Matic relocates its China operations to a new, state-of-the-art facility in Suzhou. The 2020 move, driven by regional rezoning, strengthens our capabilities and reaffirms our long-term commitment to the Asian market.

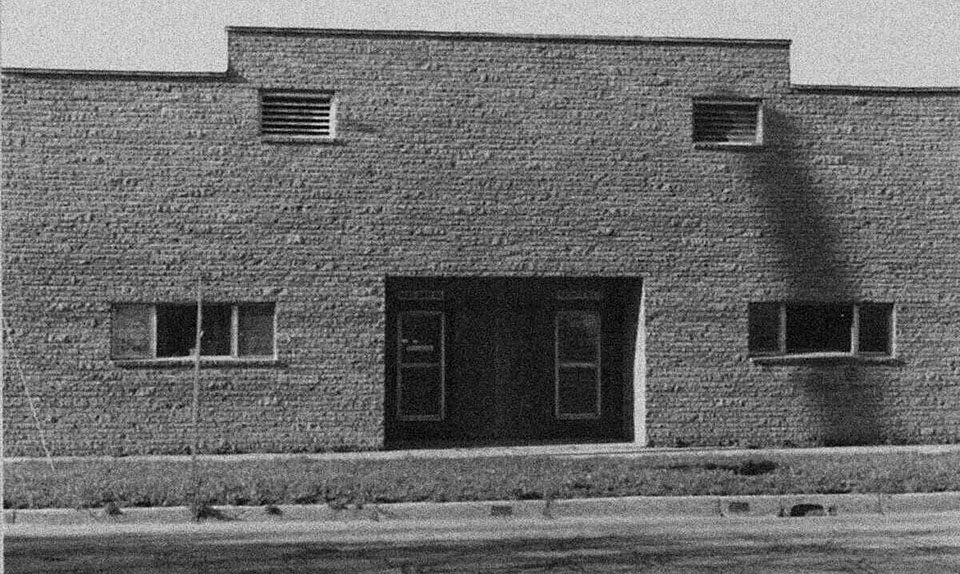

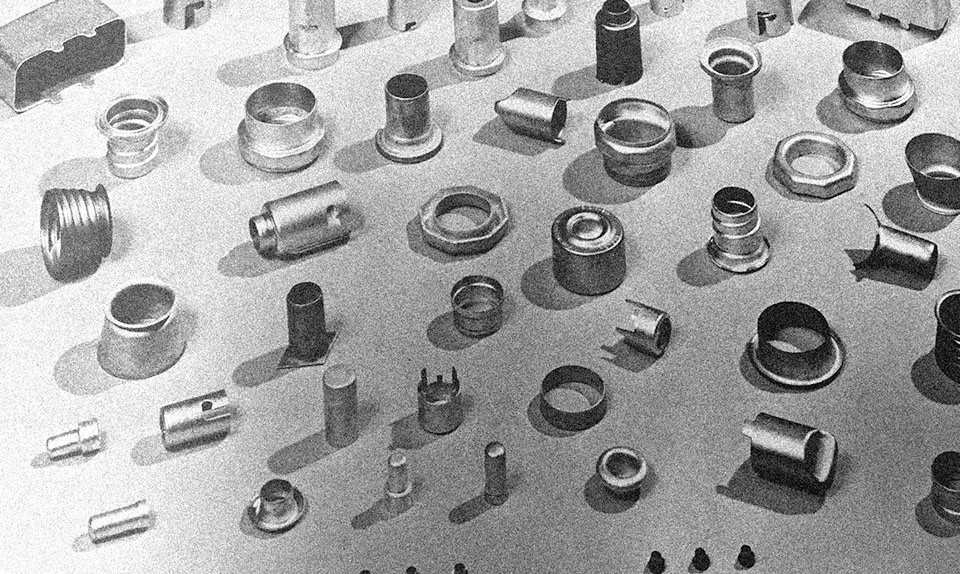

Industry Leading Facilities & Technology

With state-of-the-art high-speed transfer presses that range from 5 to 600 tons in capacity, we can accommodate complex geometries and configurations without costly secondary processes. Moreover, our team is continuously innovating for the sake of our customers, seeking to lead our industry in responsible manufacturing methods that make deep draw metal stamping better across the board. With a Value Add/Value Engineering (VA/VE) department we keep finding new ways to improve quality, design and pricing for our customers.

To adequately serve a wide audience, we work in stainless steel, low carbon steel, aluminum, copper, brass and more. For more information on our metal stamping processes, locations, or how our team can provide for your company, let’s chat.