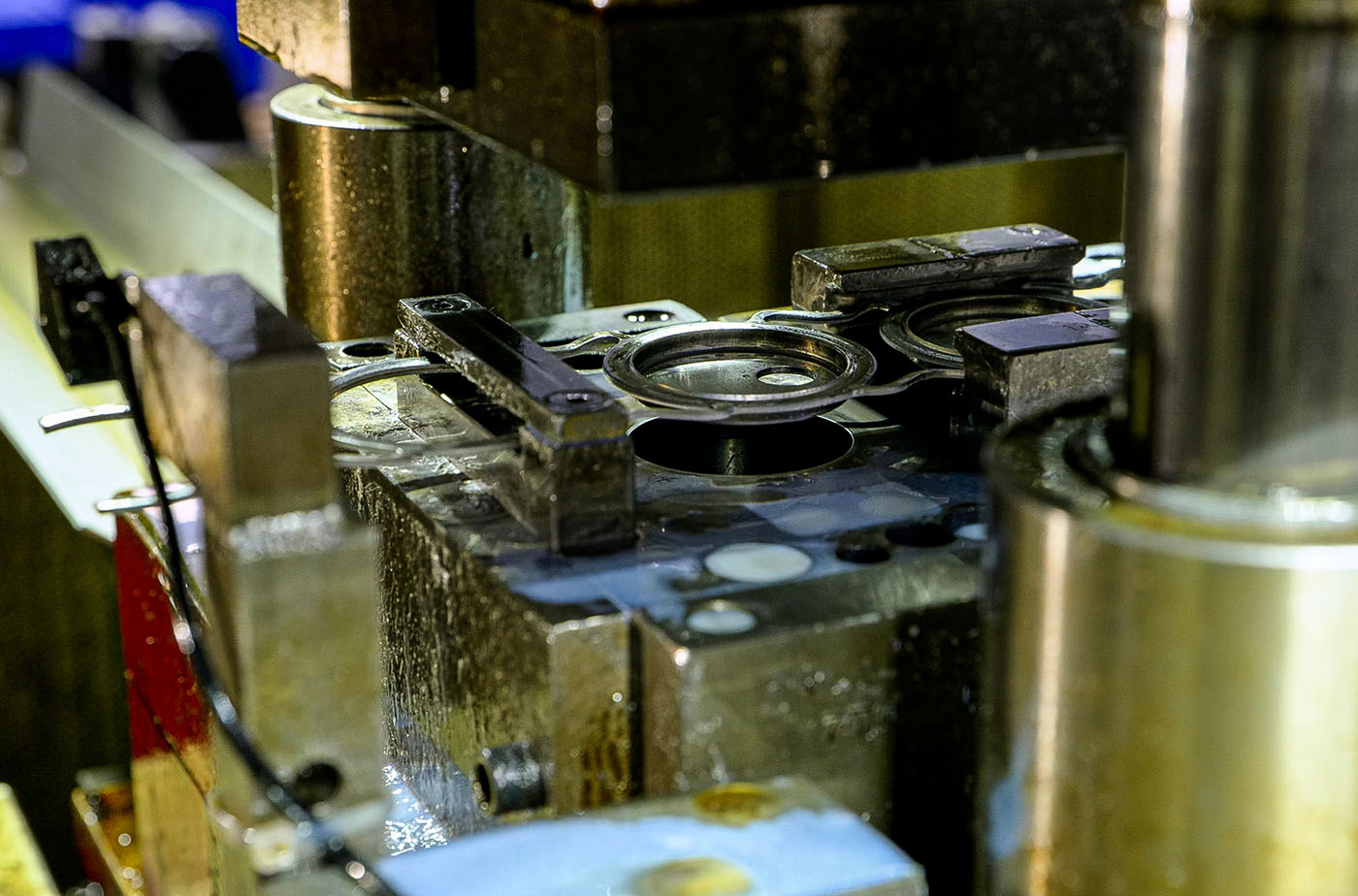

Progressive Die Stamping

In progressive die stamping, the press uses an automatic feeding system to push a strip of metal through each stamping station. Each station performs one or more operations throughout the part-production process. The final station serves as a cutoff operation, which separates the finished part from the carrying web which, along with metal punched away in previous operations, becomes scrap. With each stroke/cycle of the press, one or more completed parts get cut off and removed from the die.

Learn more about why our metal stamping company offers this manufacturing method below.

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur.

Sed ut perspiciatis unde omnis iste natus error sit voluptatem accusantium doloremque laudantium, totam rem aperiam, eaque ipsa quae ab illo inventore veritatis et quasi architecto beatae vitae dicta sunt explicabo. Nemo enim ipsam voluptatem quia voluptas sit aspernatur aut odit aut fugit, sed quia consequuntur magni dolores eos qui ratione voluptatem sequi nesciunt.

Overview of Progressive Die Stamping

To begin the process, we place the progressive stamping die into a mechanical or servo driven stamping press. As the press cycles, the top die moves up, which allows the material to feed through the die. When the top die moves back down, the die closes and performs the stamping operation. As the part advances to additional stations in the press, our quality assurance procedures ensure the strip aligns with the tooling within a few thousandths of an inch. Bullet shaped “pilots” enter previously pierced round holes in the strip to guarantee maintained alignment.

Progressive Die Presses vs. Other Production Methods

Progressive dies are one of the most popular and quickest methods for producing parts. Progressive dies utilize some of the original strip or coil, called a strip carrier, to tie parts together, which differs from the production method of line or transfer dies. Different carrier designs are needed to produce different types of parts.

Progressive dies can meet a wide range of production needs with their ability to produce as few as 7 or 8 parts per minute and up to 1,500 parts per minute. Unlike transfer or line dies, all stations are mounted on a single common die set. The timing and sequence of these stations are programmed to allow the piece part to be fed ahead with a constant progression or pitch. Multiple parts can be made with a single press stroke since many parts can be tied together.

Advantages of Progressive Die Presses

Progressive metal stamping allows for efficient, high-volume runs of small parts. The tight tolerances of these presses make them ideal for use in many situations across various industries. Additional benefits of using a progressive die press include:

- Speed: The automatic feeding system of the material allows the stamping machines to run at high speed with minimal downtime, which leads to faster production times and more efficient cycle times.

- Low Labor Costs: Progressive die presses with proper sensing systems allow them to run unattended, reducing the amount of operators needed to oversee machines.

- Run Length: The automatic feed of material allows for long production runs, leading to a greater volume of completed parts in a shorter amount of time.

- Minimal Scrap: With any manufacturing process, there will be scrap metal. However, progressive die presses use optimized tool designs to minimize the amount of waste.

- Low Part Cost: Combining all of the advantages above reduces part costs.

- Quick Setup: Only one setup is required when using a progressive die press to produce parts, which saves you time compared to other metal stamping methods.

- Complex Geometry: The build of die stations allows for the creation of unique parts with increased precision.

- High Repeatability: Progressive press dies are hard-coated, meaning they can withstand large-volume productions without degrading. High part-to-part repeatability ensures uniform quality throughout the entire production run.

Ask Us About Progressive Die Stamping

Trans-Matic is a global progressive die stamping company with decades of experience perfecting our processes. The result is a state-of-the-art facility built to accommodate diverse project requirements. Depending on what is needed, we match each project with the ideal manufacturing process to maximize product quality and minimize cost. Fill out our online contact form today to schedule a consultation and learn more about how our services can benefit your business.